- Canadian Tire Motorsports Park is historically good venue for Dyson Team.

- Team returns to full strength with return of 2nd Continental GT3.

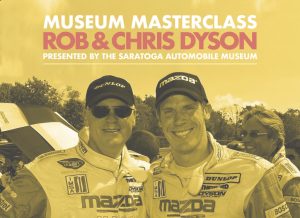

(Poughkeepsie, NY, 13 May 2015) Following a hard push, Bentley Team Dyson Racing returns this weekend in full strength to the Pirelli World Challenge at Canadian Tire Motorsports Park, a venue that has brought the team great success in the past.

“Over the years our team has always run strongly at this track, and I expect we will this weekend as well,” said Rob Dyson, the team’s founder and CEO, noting the five race wins and five pole-position starts Dyson Racing has scored at Canadian Tire Motorsports Park. “The new owners have changed the name of the track from Mosport and made lots of positive changes to the supporting infrastructure. But the actual track is the same as always – fast, flowing and challenging. From a driver’s perspective, it’s not for the faint of heart.”

Driver Chris Dyson, a pole and race winner at the track when it hosted the American Le Mans Series, says it’s one of his favorite circuits, and one that’s well suited to the Continental GT3. “I’ve always loved racing there. It’s very fast with lots of natural-terrain elevation changes,” he said. “The Bentley is great in fast corners and that will be a huge advantage at this track,” noting that the Continental GT3 has good acceleration and makes excellent downforce at high speeds, a major advantage at Canadian Tire Motorsports Park, where most of the turns are either fast or very fast.

Addressing the specifics of the circuit, Dyson said “Turn 2 is fast, over a slight crest and off-camber, so you have to get it exactly right or the consequences can be severe.” Dyson also noted “the run uphill from Turns 5 & 6 (which are really one turn and the only slow part of the track) leads onto the back straightaway over a blind crest. Blasting uphill there and through the esses before pit straight is a thrill every lap. The circuit is one of those rare places where every corner seems more exciting than the last one! As road racing circuits go, there are none quite like this place.”

The Return of #20

While Chris Dyson’s second-place finish in the #16 Continental GT3 last month at Long Beach, Calif. last month represents the team’s highlight of the season to date, it was also the race where an overambitious, video-gamer turned rookie real-world driver rammed Butch Leitzinger’s #20 Bentley into a wall. The damage was sufficiently severe that the car could not be repaired in the four days between Long Beach and the beginning of the next race meet at Barber Motorsports Park in Birmingham, Ala.

“It was tough being at Barber and not driving,” Leitzinger said. “But I wanted to be there with the team. I’m really pleased that my car is ready to race again and grateful to everyone on the crew who put in an extra effort to get it back together. I can’t wait to get back behind the wheel and justify all their hard work.”

Leitzinger, a former race winner at the track during the days it was called Mosport, wasn’t exaggerating about the amount of work necessary to repair the #20 Bentley. Disassembly of damaged components – and there were a lot of them – began in the paddock in Alabama, where work on an inventory of replacement parts began. But the biggest challenge was dealing with the damage to car’s basic chassis structure, the unibody on which every other component is attached. According to team manager Mike White, the parts of the chassis where the suspension is attached were moved several inches and twisted out of shape as well. Had it been a road car, the insurance company would probably have written the car off.

“We looked into getting a new tub from England” White said, referring to the basic chassis structure that includes the welded-in roll cage. “But by the time it would have arrived, we’d have basically had a day to install all the components, including wiring harnesses and plumbing. Instead, we decided to see if we could fix the bent one.”

The first step was locating a high-quality collision repair facility with a frame machine where the tub of the car could be pulled back into its original shape. But because each corner of the car’s the suspension needs to be perfectly fitted to the chassis and in perfect relationship to the other three suspension assemblies, the precision necessary for the repair of a race-car chassis is substantially greater than for an ordinary road car. That meant bringing in a FARO Arm, a special portable 3D computer measuring machine, and a technician capable of operating it. Armed with a set of coordinates supplied by M-Sport, the company that developed the Continental GT3 for Bentley, the FARO Arm was able to guide the final elements in the five-day process of repairing the chassis.

The chassis arrived back at the Dyson Racing facility last Friday, leaving the weekend and Monday to install all the components. “At one point over the weekend there were nine technicians working directly on the car at the same time,” White said. “But seeing the transporters leave for Canada early Tuesday morning with two great potentially race-winning race cars on board, I think made all the hard work worthwhile.”

Race Schedule (All Times are Eastern Time Zone)

Friday 15th May

| Session | Start Time | Finish Time | Duration |

| Practice | 9:35 am | 10:20 am | :45 |

| Qualifying | 3:05 pm | 3:50 pm | :40 |

Saturday 16th May

| Session | Start Time | Finish Time | Duration |

| Race 1 | 1:40 pm | 2:30 pm | :50 |

Sunday 17th May

| Session | Start Time | Finish Time | Duration |

| Race 2 | 3:00 pm | 3:50 pm | :50 |

Bentley Team Dyson Racing’s performance can be followed via live stream at www.world-challengetv.com.

– ENDS –