Paintings and sculptures get signed. Books and poems have the author’s names on the cover. Movies and videos have credits a mile long. And yet race engines that prove themselves in the most extreme of environments run in anonymity race in and race out.

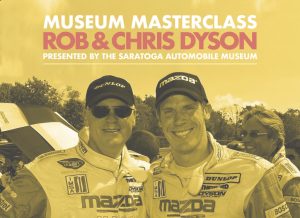

Taking the Mazda MZR-R engine that won the 2011 American Le Mans Engine Manufacturer Championship and powered the two Dyson Racing Lola LMP1 entries in the ALMS as an example, we will walk you through the build process and show you what it takes to create over 500 hp from thousands of parts and components and let you decide if this is as much an act of creation as applying paint to a canvas or pen to paper.

It takes approximately eighty hours for Advanced Engine Research to build the Mazda MZR-R (AER P70) engine. And the actual assembly is in many ways the end of the process. Most of the engine’s components require major lead-time. The two groups that have the longest lead-time are the machined steel components like crankshafts and gears – they require three to four months to manufacturer – and cast components like the head and block which take two to three months. When the cast components arrive at AER, they require multiple intricate machining steps to finish and are machined in house, taking up to four weeks for completion of complex parts like the head.

This is one of the areas where major costs are incurred in building an engine: a billet of metal is inexpensive, but the time, effort and number of steps required to turn it into a crankshaft, make it an expensive item when finished. And the same with a casting – in itself, relatively inexpensive, but to turn it into a head, block, or pump assembly requires significant amounts of machine time.

Once an inventory of all the parts needed to build an engine are assembled, a kit of parts will be issued to the engine build shop and there will be a builder allocated to a specific build of an engine. The builder will perform the initial checks on the parts and than start to assemble the engine from the bottom end until the engine is complete as a short engine with pistons, rods, crankshaft, and sump. This will take about two days of work. The cylinder head takes another day to assemble with its valve springs, collars, and followers. The two halves of the engine are than put together as an assembly with the head torqued up to the block at which point it starts to resemble a more recognizable MZR-R engine. The camshafts and gear sets are added to the cylinder head and the front of the engine. The valve train is than timed to give the correct valve timing. This is one of many checks performed during the engine build that also include compression ratio check, piston to valve clearance and cam timing. The front cover and the cam cover are than assembled together with the inlet system and the sensor box and the interface to the ECU, at which point it becomes a finished engine, but still not ready for shipment.

Once it is assembled, it is taken to a dyno at AER. There are two dyno test cells, one of which is dedicated to the two-liter turbo LMP engine. If it is a new build or significant rebuild, there is a run-in procedure that allows the bearing surfaces, pistons, rings, liners and the valve train parts to bed in. Once that is completed, there is a power test on the dyno and the engineering team will look at all the engine health parameters and analyze the results and compare to previous engines of that specification to make sure that it is within tolerance. With that approval from the engineering team, it will come back to the build shop for final preparation and the fitting of any ancillary parts or fittings that are specific to the Dyson Lola chassis. The engine will be put in a special engine crate and air freighted to New York or the racetrack where it finally gets to do its job.

The first race engine of the 2011 ALMS season, P70-02, was installed in Dyson Racing’s #16 G-OIL/ModSpace/Construct Corps Lola Mazda coupe before Thursday’s night practice at this year’s 12 Hours of Sebring. It acquitted itself quite well. Sebring is a track notoriously tough on a car and the engine is under wide-open throttle over 70% of the time, every lap. P70-02 ran without a single mechanical issue during the 12 hour race, placing sixth overall after 1238 miles of racing and second among the ALMS LMP1 entries. The engine remained in the car for the next race, winning the pole and coming in second at the Long Beach Grand Prix.

One mis-torqued bolt and P07-02 would not have lasted very long on the concrete runways of Sebring. Here is to the engine builder, perhaps the most unrecognized of the many unsung heroes that make up the backbone of racing.