Gasoline is a Johnny-come-lately. The automobile started out on bio fuels. Nicolaus Otto, the inventor of the four-stroke engine in 1876, ran his engines on ethanol. Rudolph Diesel ran his first single cylinder engine in 1894 on peanut oil and Henry Ford designed his Model T to run on ethanol.

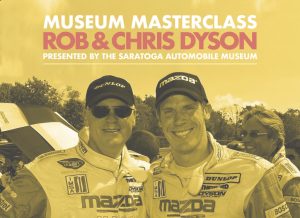

A new chapter in this historical narrative was written last year at the last two races of the American Le Mans Series. Dyson Racing ran BP’s new biofuel blend with isobutanol in the #16 LMP2 Mazda Lola coupe at the Petit Le Mans and Mazda Raceway at Laguna Seca. This successful test led to the 2010 approval from the ALMS for BP Biofuel IsoButanol’s use in the prototype classes. Dyson Racing ran it during the just-completed 2010 race season and gave the fuel its first overall ALMS win at Mid-Ohio in August. From the first use of a rear view mirror on Ray Harroun’s 1911 Indianapolis 500-winning Marmon, to the pioneering use of isobutanol in a race car, racing continues to drive beneficial advancement.

Isobutanol is an organic alcohol that has four carbon molecules compared to ethanol’s two, giving it 25% more usable energy. Like ethanol, it can be made from sugar cane and corn, but can also be made from lignocellulosic sources like crop waste and purposely grown non-food plants such as switch grass and energy grass. Using those materials produces a smaller carbon footprint than gasoline or ethanol. Using biomass can also produce a negative carbon imprint when the carbon dioxide absorbed by the growing crops offsets the emissions produced when they are cultivated, processed and burned in engines. When burned in an engine, isobutanol produces carbon dioxide but no SOX, NOX or carbon monoxide and is much less evaporative than ethanol or gasoline.

The next step is the development of technologies to convert sugars produced by macroalgae into isobutanol. The goal is to take the most land-efficient feedstock (algae) and use it to produce the most gasoline-like biofuel in a cost-efficient manner. The macroalgae aquafarming project will be conducted in Southern California by Butamax™ Advanced Biofuels LLC, a joint venture between DuPont and BP. Butamax will be responsible for the commercialization of the resulting technology. The expectation is that using aquafarmed native macroalgae to produce isobutanol will reduce greenhouse gas emissions significantly compared to petroleum.

“Racing has the responsibility to lead by example. Motor racing’s DNA is not just about racing,” noted Chris Dyson. “It is about pushing the boundaries of future technologies that eventually make their way into regular road-going applications. Because resources are becoming scarce all across the planet, we need to have a new dialogue about how we are going to live in the future. The American Le Mans Series got on board with the “Green Initiative” very early on and for the past five years, they have added a new or advanced fuel each year. Our engine partner, Advanced Engine Research, worked hard developing the Mazda MZR-R engine for isobutanol, and the immediate results at the Petit Le Mans last year spoke for themselves. Our alignment with Mazda, BP and Castrol is the perfect fit because they use racing as a platform for developing new technologies in a rapid and advancing atmosphere. Technologies and fuels now used in the ALMS are setting the stage for positive and ecologically conscious developments for consumer cars in the future.”

Isobutanol has many advantages compared to first generation bio fuels. Its longer hydrocarbon chain gives it a molecular structure that is closer to gasoline, resulting in better fuel economy. It can be blended in gasoline at higher concentrations than ethanol without the need to modify vehicles, thus allowing greater concentrations of renewables in the transportation mix. It can be used with ethanol to help improve the performance of ethanol/gasoline blends. Compared to ethanol and methanol, it does not absorb water and does not affect the metal and rubber components of a car’s fuel system. Isobutanol can be used in existing pipelines and storage tanks, eliminating the need of truck and rail transportation and expensive infrastructure investment required by first generation biofuels.

The Mazda MZR-R four-cylinder turbocharged engine developed by AER and used in Dyson Racing’s Lola coupe is a natural development tool. “The smaller turbocharged engines of the ALMS offer a valuable test-bed for evaluating fuels that can offer the best performance, and Mazda brings a wealth of knowledge and experience that will help us develop the best fuels,” said Tim Hayes, vice president, strategic accounts for BP. “BP sees this as a great opportunity to test and learn about the performance and capability of these advanced fuels and their respective components like isobutanol and ethanol.”

“We are pleased to take the technical relationship between Mazda and BP to this next step,” said Robert Davis, senior vice president, Product Development and Quality for Mazda North American operations, and the man responsible for the company’s North American motorsport programs under the MAZDASPEED Motorsports Development banner. “This is a great opportunity to combine learnings from advanced fuels with a production-derived 2.0-liter turbocharged MZR-R engine. It shows the commitment that both Mazda and BP have to understanding advanced clean, efficient, and environmentally sensitive technologies, and leveraging the learnings to bring relevant technologies to the public in the future.”

The rear view mirror from the 1911 Indianapolis 500 is the most often quoted example of racing being the mother of invention for the cars we use everyday to go to work and take the children to soccer practice. A century of racing has produced disc brakes, high speed wipers, improved fuel injection for better mileage and less emissions, direct injection, clean diesel technology; improved traction control and ABS, metallic and ceramic brakes, electronic engine management, improved tire construction and tread designs, etc. A complete list would cover virtually all aspects of today’s’ automobile. Equally as important as these physical inventions, are the advancements that come from racing’s ability to accelerate the time to market compared to more traditional engineering channels. Designs, manufacturing processes and materials are often tested and proven in racing before being introduced into daily transportation.

Racing is a citizen in a world of finite resources. There is no better real-life high performance laboratory than motorsports to produce tomorrow’s advancements. The partnership of Dyson Racing, BP, Castrol, Mazda and the ALMS are excited to be at the cutting edge of this positive and relevant technology.