It would not be fitting to use the phrase “dumb as a post” in reference to a seven- post shaker rig. More appropriate would be the historical use of the number seven to represent wisdom, wholeness, and perfection.

It is a term frequently used in racing, but what exactly is a seven-post rig? Seven- posters actually started out as four-posters 30 years ago or so. Automobile companies used them to shake test their cars for squeaks and rattles. Each tire would have one “shaker post” to sit on and would move to simulate road conditions. (“Post” is a misnomer as it is really one of four hydraulic rams over seven feet in height that are mounted on a seismic block of concrete weighing hundreds of tons.) For a seven-post rig, you take these four hydraulic actuators and add three more that work on the bottom of the car and apply the aerodynamic downforce that the car generates, but as a zero-mass load, just like in reality. The seven- post shaker can apply all the vertical forces that a race car experiences: aerodynamic downforce, lateral load transfer, acceleration and braking.

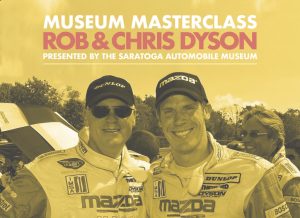

Dyson Racing recently spent some valuable time in Indianapolis before the Salt Lake race at the Automotive Research Center utilizing their seven-post shaker rig. “Among other things, the test confirmed that what we were trying to do with softer springs and more damper control in the car at Long Beach was the right direction,” said Peter Weston, Dyson Racing’s head engineer. “Testing and racing our Mazda MZR-R this year and the team’s institutional knowledge gives us a good data base on how to control the mass of the car and how to get more grip out of it. The seven-poster test helps us put together a much more complete picture. Ultimately, if you are controlling the tire’s contact patch, you are controlling the level of grip. And that is what we were able to do. We are pleased with how much transfer there is from the rig to the track. With the testing limits this year and the track sessions being short, these type of controlled tests are more valuable. They help us achieve the goal of rolling off the truck in good shape with a set-up we can hang our hat on.”

Noted driver Chris Dyson, “I was really impressed with the accuracy of the rig’s findings and by how seamlessly the changes transferred to performance in the car. The seven-post rig technology has really moved on tremendously in recent years, and we have incorporated the rig as a very useful supplement to our on-track testing.”

The most basic tenet of racing is that a race car is only as fast as the size of the tire contact patch with the road. And that is what a seven-poster is all about: it is a tool to optimize the springs and shock absorbers to minimize tire load variations while maintaining good body motion control. In plain words, the rig generates information that helps to keep the car’s tires on the road. The seven- post rig allowed Dyson Racing to try a large number of spring and damper combinations in a controlled environment, in a much shorter period of time than if they were at the track. “The tire is the only part of the car that touches the road,” said Weston. “You don’t want a tire contact patch going from the size of a dinner plate to the size of a quarter and back. What the driver feels is the minimum level of grip that he has. So he will drive around the corner assuming he has tires with a minimum contact patch of a quarter. You are leaving a lot on performance the table.

“There are so many variables during a test at a race track: track temperatures, traffic, changing car weight as you burn off fuel, tire wear, whether the driver has just had a big meal, etc. At a track, there are so many conflicting inputs that it is easy to miss the results of a change. With a seven-poster, you are in laboratory conditions with every hour the same as the previous one. So you go to the test with an assortment of dampers which you have pre-built based on a large amount of homework looking at data and mathematical models. So the most basic result you want from the test is to match dampers to springs to give you the combinations that give you the minimum amount of contact load patch variation.”

And the possibilities grow from there. Automotive Research Center has software that allows teams to simulate race laps and complete race distances at the track of their choosing. The seven-post rig has hundreds of sensors built into it that makes it a virtual race track as it simulates (and measures) all of the vertical forces the car experiences at the track. With sanctioning bodies continually moving to limit track testing, the seven-poster becomes an even more efficient tool to explore a car’s capabilities without the expense of track testing. Plus you are eliminating the variables of inclement weather, and the cost of the wear and tear on the car. At a cost of a couple million dollars, it is an expensive tool, though like wind tunnels, more teams are installing their own machines.

But computers will not replace drivers. “Laboratory testing, done with a good plan, is going to be more efficient in going through a list of different changes than track testing is. The driver is the ultimate arbiter. These changes must be tried out and proven on the race track. The driver must feel comfortable with the set up. It is that “seat of the pants” sensitivity that is the ultimate computer in analyzing the incredibly complex interactions between the car and track. However, most drivers don’t like the car to move around too much, to roll, to pitch react, but his might be the result of a test that improves tire grip and might be faster than a stiffer, less mobile setup. That is when the driver and the computer have to cohabit.

“The use of wind tunnels, engine dynamometers and seven-post rigs allows you to come to the track much better prepared. A technical director I once knew, used to say that a race car has a lap time designed into it – from the moment it leaves the drawing office, it has an ultimate lap time designed into it and the only thing a race engineer can do is slow it down. So it is just a question of how little you slow it down! The race engineer that makes the least amount of mistakes will be the best one. And the more information you have, the better. Our job as a team is to give Chris, Butch, Guy and Marino the best platform for them to showcase their skills and talents and to win races.”