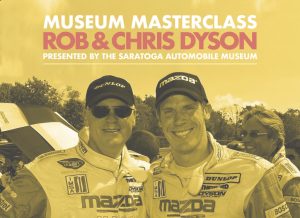

POUGHKEEPSIE, NY, MAR. 4, 2004 — In the biblical story of David and Goliath, diminutive David used a slingshot to slay the giant Goliath. For Dyson Racing, a small and lean team from upstate New York that over the past two decades has taken on and beatens ome global giants, the equivalent of a slingshot has been the team`s ability to forge strong and lasting technical alliances with partners both local and from around the world.

“Racing is a complex and highly technical activity,” said team principal Rob Dyson. “Success ultimately comes down to the quality of the people who are working for you and with you, and everyone`s ability to communicate with one another. And that is an important differentiation. Our employee roster tends to be very stable, so internally our guys know how to work effectively with one another. But no matter how many people you have working in your shop, you are also dependent on your external partners. Even the major Formula One teams, with hundreds of employees, call on outside partners to provide tires, electronics and engines.”

Dyson notes that with just 12 full-time employees working in its Poughkeepsie shop, the team depends on having excellent working relationships with the organizations that supply key components. “We have worked with both Goodyear and Bosch for nearly a quarter of a century,” Dyson said. “Overthe years, our guys have gotten to know their guys pretty well, so communication on technical matters is quick and clear. This matters.”

Choosing When To Change

Not that everything is set in concrete when it comes to technical partnerships. Since its arrival at the highest echelon of North American sportscar racing twenty years ago, Dyson Racing has won more races and championships than any other top-tier professional sportscar racing team. The team`s initial successes came with prototype cars from Porsche in Germany. Then, after nine years the rules for sportscar racing changed, and Dyson Racing began a long and fruitful association with Indianapolis-based Riley & Scott, campaigning its Mk. IIIto victory twice in the Daytona 24-hour race, and to a combined total of 15 driverand team championships.

“We had a wonderful relationship with Riley& Scott for many years,” said Chris Dyson, who in addition to his outside business activities, as Sporting Director oversees the team`s day-to-day operations.”And they are a terrific car company. But changes in the rule package inthe American Le Mans Series (ALMS), where we chose to compete, forced us to find an alternative chassis manufacturer. We are fortunate to have developed the same sort of excellent relationship with Lola Cars International in England.”

Team manager Randall Kelsey, who at 26 is in his 11th season with DysonRacing and serves as an example of the stability of the team`s internal relationships,notes with satisfaction the quality of the Dyson-Lola working relationship. “We may be separated physically by the Atlantic Ocean, but our lines of communication are quite strong and we get everything we need from them.”

The results are clear. In 2003, the first full season running the Lola, Chris Dyson captured the American Le Mans Series 675LMP Drivers Championship and the team matched the speed of the vaunted Audi factory team, with Dyson drivers James Weaver and Butch Leitzinger winning overall at Sonoma, Calif. last summer.

“We have two English drivers with Andy Wallace and James,” said Rob Dyson, “and two Americans with Butch and Chris. James has driven for us since 1987 and Butch and Andy since 1995. And like Randall Kelsey, Chris has literally grown up with the team. He does not remember when he was not going to races with us. Everyoneworks well together and this kind of stability means that when we are setting up the car at the race track, there is not a lot of wasted motion.”

When examining Dyson Racing`s most recent successes, the last piece of the puzzle is represented by another overseas partner, Advanced Engine Research (AER). “The high-tech rules we race under in the ALMS meant that we needed to develop a partnership with an organization that could design, develop and manufacture a very high-technology pure racing engine for us,” Chris Dyson noted. “In AER we found that partner. We have worked together on the development of the engine, giving them our feedback. And they have been tremendously responsive.

“Last year we were able to match the Audi`s performance most of the time,” the younger Dyson observed. “With our partners support, we have made a good deal of progress over the winter, and it is our expectation that this year we will be fully competitive with them and everyone else from the first race this month at Sebring and at every other track on the schedule.”