As part of our series of Team Chats, we now give you an engineering view point with Peter Weston, Technical Director, Dyson Racing

“Could you talk us through some of the different types of tracks that you encounter in the American Le Mans Series and how you approach them from a race engineer’s perspective?”

Sebring

“Sebring is like two separate races: what set up you run during the day vs. the night time racing. Racing at night presents its own challenges. The air temperature drops first relative to the track temperature. This helps the engine, as the air gets cooler and denser, resulting in potentially the fastest laps of the race, with hot tires and cool air. At this point too, the rear wing works better than the front diffuser, as the ambient air temp affects the rear wing efficiency more than the front diffuser. This might bring a period of understeer to the balance. Gradually, the track cools down and the front diffuser wakes up again, rebalancing the car. However, with both the rear wing and the front diffuser working better than they did in the heat of the day, the overall downforce has gone up, which impacts the ride height. You have to take this into account when signing off on the setup before the race, as you do not want to have to change it during the race.

“And you have to get the headlights right. You will have paid extra attention to the setting of the headlights in night practice. The nighttime nose is normally one with clean headlight lenses and perhaps an extra headlight. Some teams keep their extra headlights in a separate nose, out of harm`s way, over the pit wall, until it gets dark. A daytime nose can have just two lights, making the cost of any damage to the nose, a little cheaper. A different aero setting can be put on the night time nose, but normally the balance is set by the rear wing (which does not change necessarily), so changing just the front will imbalance the car.”

Mazda Raceway Laguna Seca

“The resurfacing of the track and the work they have done over the years for the MotoGP has improved the track. At Laguna, tires are always the key. The track is dusty and has very low grip. There have been sessions in years past where the first session is almost like a wet session with rooster tales of dust coming up off the back of the cars like water! Low grip mimics a lot of street courses and so soft tires are often better. Plus the race is unusual in that it starts in the afternoon and goes into the evening and there is a big temperature difference. The temperature will go down 20 degrees in the last hour. So you have to keep in mind that the tire pressures go down as the temperature goes down and you have to keep the tires current with the constantly changing conditions. Some teams will double stint the tires at Laguna and that can be a mistake because in the last hour, tires have thinner rubber on them from being worn down and the rubber gets cold and then the track temperature goes down and then the tire pressure go down so you get less temperature in them and it all negatively feeds on itself.

“Laguna is a higher downforce track and you adjust the ride height accordingly so you are not bottoming out any where. But with the surface being smooth, you can run it lower than you normally would for a high downforce set up.”

Miller Motorsport Park

“The Salt Lake track presents its own challenges. The circuit is unique: it is very smooth but abrasive. The sand at Miller can be a problem, especially if it’s windy and there is a sand storm, which there invariably is. The tires are normally very smooth at Miller, as they have been polished by the sand. It is like driving on a very fine sand paper. Grip can be at a premium, but it is also very smooth, like a European track, so you can take liberties with stiffer springs and lowering the ride height. Aero is compromised because of the altitude, with the barometric pressure being normally 850 millibars, giving you only have about 70% of the downforce you have at sea level. So you need a fair amount of stiffness just for the sheer lateral load and stability of the car. You need to go for mechanical support to keep the car upright to make the most of your aero because every last pound of aero is vital around Miller. Which means you end up with a curious compromise. Normally when you have a low aero circuit, you do not need to run as stiff – but Miller is one of those funny circuits that is the exception to that rule.

“And the thinner air also means your cooling does not work as well, so it is harder to keep engines and brakes cool, also exacerbated by the regular high ambient temperature.”

Mosport

“Mosport is fast: it is the highest average speed track that we come to. There is really only one braking zone, and that is turn five at the bottom of the hill. You can breathe on the brakes at turn three and if the car is good, you can go from the exit of ten on the pit straight and not lift off again until you get to turn three. You can go through turns one and two in sixth, so the vertical loads on the car are immense: the wheel loads at Mosport are the highest we see all season. Through turn two and turn four we see one g vertical load into the car as well as all the aerodynamic and lateral forces. So the tire loads are huge. With the set up, it becomes a balance between how stiff you can run the car to support those vertical, aero and lateral loads, and how soft you can run the car for turns 5a, 5b, and nine and ten because these are the slow corners. For an ultimate lap time, you want to run more downforce than you would do for running in traffic. It is always a yo-yo between how much drag you run for the race and how much downforce you run for a qualifying lap. Generally downforce will save a tire because the car won’t slide as much but whether you have high downforce or low downforce, the key word is balance: you want to keep the car balanced through the all the high speed corners so the driver has confidence. You can have all the downforce in the world, but if the car isn’t balanced, if it has understeer or oversteer, the driver will not be able to make use of it. So it is all about tire management, keeping the car balanced and keeping it off the ground with the softest springs you can. There are similarities with an oval – with an oval you have banking and you have a lot of vertical g loading going through the car due to the banking. It is not dissimilar to trying to engineer a car at Daytona where you are trying to keep the car off the ground on the banking and yet have as much grip as you can in the infield sections.

“Mosport is also an old track with concrete patches. The layout of the track has not changed; it hasn’t been blighted by chicanes. The layout is as it was in the 1960’s. The tarmac is very old and with the extreme corner loads, the tarmac has become worn over the years, so turns two, three, four, eight and ten, all have big concrete packages and the line through turn ten is one big concrete patch. This presents its own challenge as does the fact that the tarmac around those patches is lower than the patch itself. So you think you are doing well with your ride height management and than a concrete patch that is 3/8″ higher than the tarmac comes up and smacks the bottom of the car, and right where you don’t need it – at maximum load. The other problem is the level of grip on the concrete is vastly different than the tarmac and you have the tire traversing on and off the concrete in the middle of a corner. So you try running a slightly harder tire that is not so sensitive going from tarmac to concrete.”

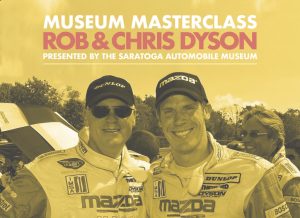

Peter Weston’s career includes working at Lotus, March, Lola and Pacific Racing. At Lotus, he was the race engineer for F1 drivers Johnny Herbert and testing engineer for Alex Zanardi. During his time at Lola, he got to know Rob Dyson and Rob invited him to join Dyson Racing in 2002. Since than he has been responsible for engineering the cars for current drivers Chris Dyson and Guy Smith along with long-time Dyson drivers James Weaver, Andy Wallace, and Butch Leitzinger.